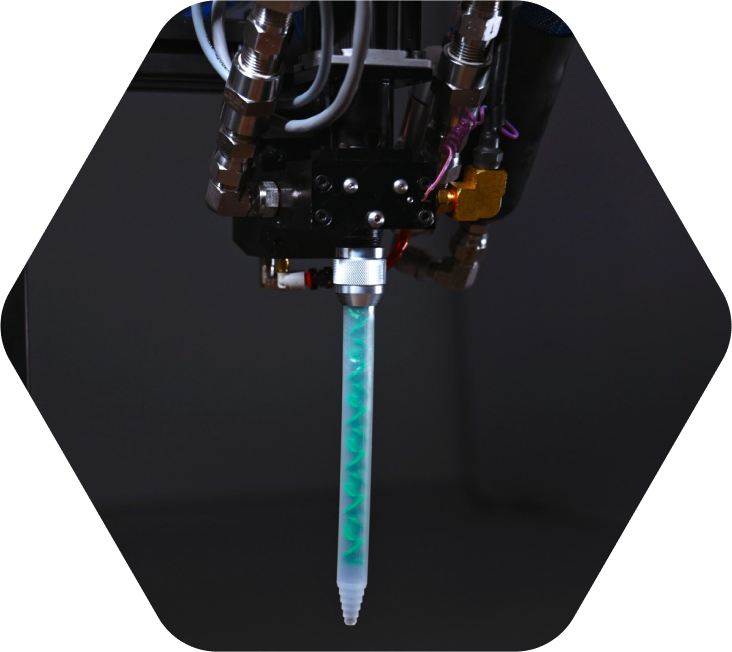

Fluid Research® S-Series Meter Mix Dispense System

The S-Series features a compact, two-component system engineered for efficiency and high-quality performance, with real-time monitoring and an integrated Coriolis flow meter. Engineered for nearly any general industrial application, process, or material and designed for maximum efficiency and superior performance.

The S-Series monitors dispensing, flow rates and multiple variables, manages numerous programmed shots, and offers:

![]()

![]()

MACHINE FEATURES

- 1 to 30 gallon stainless tanks

- Static-dynamic mixing

- Stat-a-Seal dispense head

- High & low level sensing with auto refill from bulk

- Customizable Material Management Unit

- Desiccant dryer

- Vacuum degassing

- Compatible with NeverEmpty™ Material Managment Unit, pail, or drum rams

MATERIAL COMPATABILITY

- Polyurethane Foams & Elastomers

- Methyl Methacrylate (MMA)

- UV-Acrylate

- Epoxy

- Silicone

- Highly Filled Materials

SYSTEM ADVANTAGES

![]()

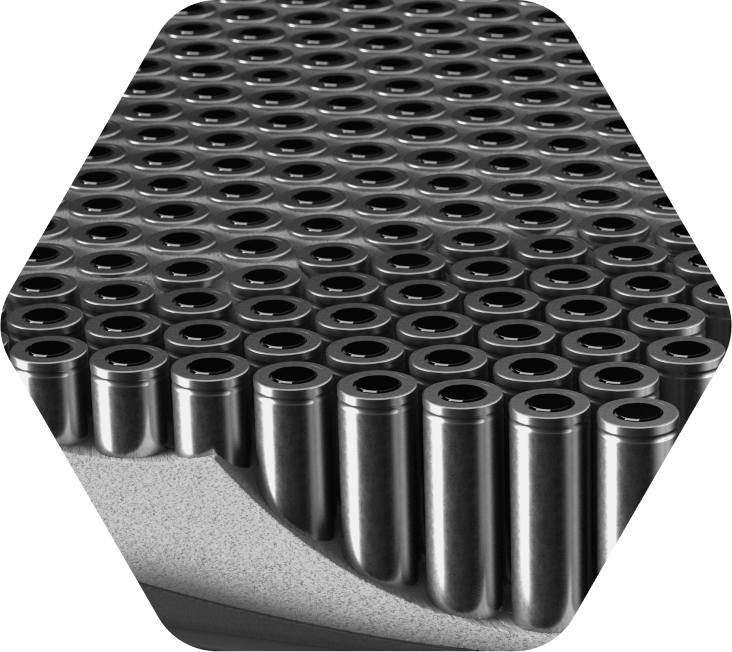

FEATURED SOLUTION: H.B. FULLER® EV PROTECT™ 5006 FLAME RETARDANT ENCAPSULATION FOAM

H.B. Fuller® EV Protect™ foams are flame retardant polyurethanes designed for potting and encapsulation of battery cells and modules. These foams help to minimize thermal propagation risks and provide noise, vibration, and harshness benefits.

The EV Protect™ 5006 is H.B. Fuller’s® next generation of ultra-lightweight, fire retardant, protective foam encapsulants. The low viscosity liquid flows and self-levels at the bottom of the enclosure and after curing, creates a semi-structural foam. When applied correctly and exposed to a thermal event, the foam will absorb, isolate, and insulate the cells to reduce the chances of thermal propagation.

H.B. FULLER® FEATURED APPLICATIONS

![]()

EV Bond: Ideal adhesive solutions for battery pack modules and bonding dissimilar substrates.

![]()

EV Seal: Resealable design helps to protect battery packs from moisture, humidity, and environmental exposure.

![]()

EV Protect™: Helps isolate thermal runaway, insulate adjacent cells, and helps reduce risk of thermal propagation.

![]()

EV Therm: Helps to enhance heat transfer between battery cells and cooling systems, minimizing heat retention.

Experience the future of dispensing with the S-Series Meter Mix Dispense System. Revolutionize your manufacturing process.

H.B. Fuller® is a registered trademark of H.B. Fuller Company. EV Protect™ is a trademark of H.B. Fuller Company.

IMPORTANT: Information, specifications, procedures, and recommendations provided (“information”) are based on our experience and we believe this to be accurate. No representation, guarantee or warranty is made as to the accuracy or completeness of the information or that use of the product will avoid losses or damages or give desired results. It is user’s sole responsibility to test and determine the suitability of any product for the intended use. Tests should be repeated if materials or conditions change in any way. The user is advised to review the specific context of the intended use to determine whether the user’s intended use violates any law or infringes upon any patent(s). No employee, distributor or agent has any right to change these facts and offer a guarantee of performance.